The VPR is a cold membrane vacuum press is designed for woodworking and furniture production. Membrane press is equipped with rotary work-table, which saves production space and allow use it in small workshops.

The vacuum press can be supplied in two ways: as fully equipped vacuum press VPR-3000/25 or VPR-3000/40 and as vacuum table VPR-3000T (without vacuum system).

The VPS is a cold membrane vacuum presses is designed for woodworking as budget solution. And usually used in small enterprises and workshops for production of furniture. In complement with silicone membrane can be used for shaping of solid surface materials. The model range consist two models: VPS-1500 and VPS-3000. The membrane press equipped with oil-free pump and a system of vacuum level control.

The membrane presses of VP series are optimal solution for woodworking and a furniture production from all types of wood.

The vacuum presses are equipped with heating system which allows reduce the time of drying glue and increase productivity of production. The heating temperature monitored and maintained automatically.

The membrane presses of VP series can be used for small capacities but also for professional using.

Portable vacuum systems VPB-10 and VPB-16 for wood bending, cold veneering and laminating.

Vacuum pump capacity 10/16m3/h.

System of vacuum control and automatic pump stop.

Single-phase, 220 Volt.

Vacuum bag from pvc material.

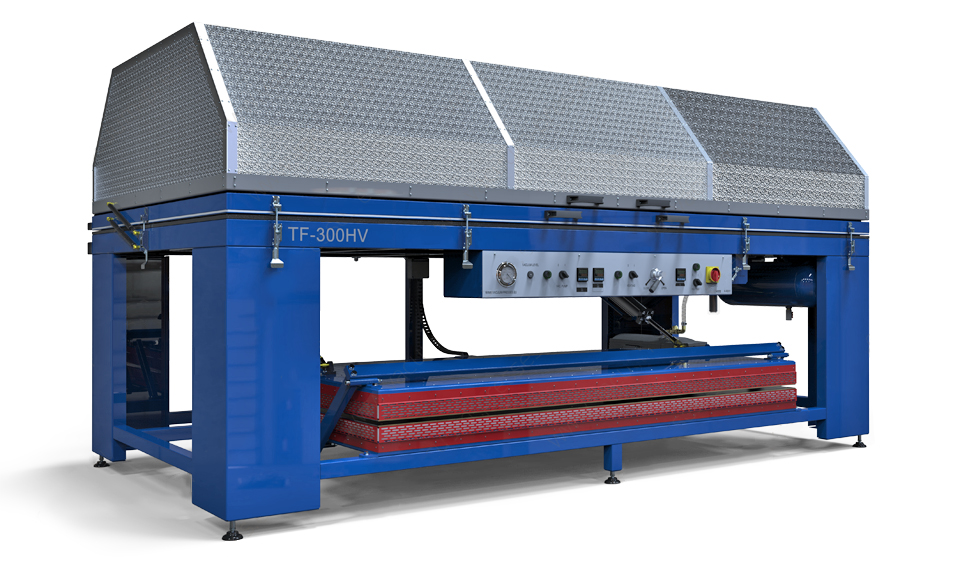

Membrane vacuum presses of TF series are specially designed for preheating and shaping of solid surface materials (Corian, Hi Macs, Staron, Hanex, Kerrock and others), as well for acrylic material and for thermoplastic forming. TF series vacuum presses are combined solution of including functions of two separate machines: vacuum press and preheating oven, and this greatly increases functionality of the press. The model range consist three models: TF-160H, TF-300H and TF-350H.

Thermoforming vacuum presses TF-300HV/350HV is equipped with heating system which allows using vacuum press for woodworking and for forming solid surfaces and an acrylic material. Acquiring of vacuum press TF-300HV/350HV you get the machine which has functions from three separate machines.

Vacuum thermo foil press VPF-2-2600/3000 is designed for 3D coating of PVC foil, also can be used as simple membrane press.

Vacuum press is fully automated and has three operating modes:

The automatic mode - a series of pressing passes automatically according to the predetermined settings. The whole process is monitored by PLC controller.

The manual mode - the whole cycle of compression is monitored by operator.

The membrane mode is designed to work with a membrane vacuum press, which can be used as a common membrane press. Press is equipped with a silicone or a rubber membrane.